Quality Control

Quality is the life of an enterprise, Z&D is committed to the quality policy of "providing high-quality bearings to the majority of users", taking the customer's needs as its own minimum working standard, and constantly meet the needs of customers. Now the company has passed ISO9001 quality management system certification.

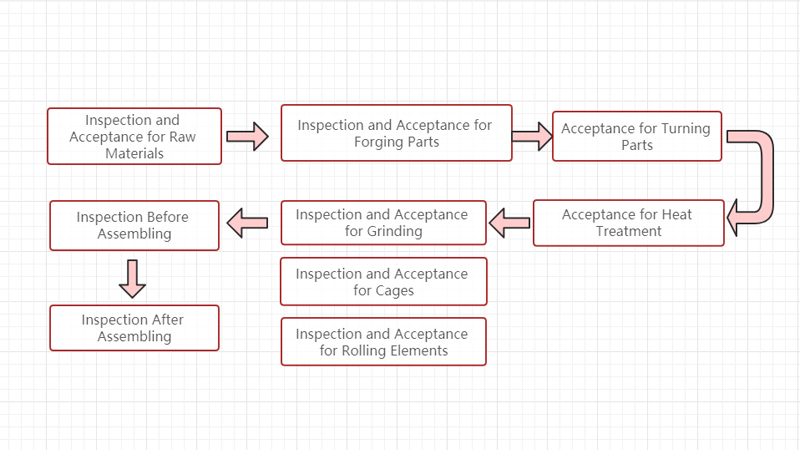

In addition, the company has established a complete set of quality control system, from the procurement of bearing steel raw materials, steel balls, cage parts, storage, production, to the inspection of finished products, packaging, sales and other processes, are guaranteed by the quality management system. In the production process, the company also adopts the work equipment with domestic advanced level: the blank process adopts CNC turning process, the heat treatment process adopts vacuum quenching, which improves the metallurgical organisation, hardness, controlled fatigue strength and other process properties of the bearing rings, and further improves the life of the bearings.

Bearing materials vary greatly according to applications and operating environments. Our expertise in materials and the centrifugal casting process assures performance and dependability for bearing manufacturers and users.

Stainless steel bearing components

Sino&Germany bearing produces a variety of stainless steels commonly specified in bearing manufacture.

Inner and Outer Rings or Races — common to all ball bearings, these rings provide a pathway on which the balls roll.

Retainer Rings – used in many bearing designs to hold components onto a shaft or into a bore.

Common alloys used

--- 440C Stainless Steel — This high carbon stainless steel has the hardenability and wear resistance specified in many bearing designs.

--- 304 and 316 Stainless Steel – bearing components made of 300 series stainless steel have the corrosion resistance necessary in some environments and applications.

--- 17-4PH Stainless Steel – another versatile, heat treatable stainless typically specified for bearing component applications requiring both strength and corrosion resistance.